Excellence in Engineering and Science

Engineering, Chemistry, Physics, Architecture and Agronomy all play a part in shaping Clever Power’s energy conversion plant design. The energy conversion process aims to:

- Reduced methane emission from landfills by diverting biomass from landfill. The Global Warming Potential (GWP) of methane (CH4) is 28 to 38 times that of carbon dioxide over a 100 year period. CH4 emitted today lasts about a decade on average, which is much less time than CO2. But CH4 also absorbs much more energy than CO2. The net effect of the shorter lifetime and higher energy absorption is reflected in the GWP. The CH4 GWP also accounts for some indirect effects, such as the fact that CH4 is a precursor to ozone, and ozone is itself a GHG. The (GWP) of methane (CH4) is 56 to 96 times that of carbon dioxide over a 20 year period. That is, reducing CH4 emission is a has more short benefit on global warming and this is the reason the US EPA started the Global Methane Initiative to reduce methane emissions.

- At Clever Power our aim is to produce Hydrogen at a cost that is competitive with current diesel prices. To do this clever Power needs to:

- Keep their plants simple to lower capital, operating and maintenance costs.

- Distribute Energy Conversion Plants so that the waste travel distance is short and the hydrogen distribution distance is also short. This implies small plants and a different approach to the tradition large Waste to Energy centralised plant.

- Only separate off the hydrogen that naturally partitions to H2. This significantly lowers water consumption and lowers CO2 emissions.

- We also focus on concentrating nutrients to enable their beneficial reuse. The nutrients like potassium and phosphorous, and trace nutrients like iron, zinc, calcium and magnesium in the biomass are recycled to into new organic rich soil which has had all the pathogens, weed seeds and sharp objects removed. Elements like nitrogen and sulphur are added via sterilised, composted manure. Beneficial bacteria is added via worm farm leachate.

- A conventional waste to energy power station has an efficiency of about 25%. A conventional coal fired power station has an efficiency between 35 to 42%. However, the energy conversion process can be between 50 to 75% efficient. If you take the waste heat from the gas engines or gas turbine and generate steam for more power generation the energy efficiency is about 50%. If you use the waste heat for process steam in processes like drying, distillation, heat or cooling then the efficiency approaches 75%.

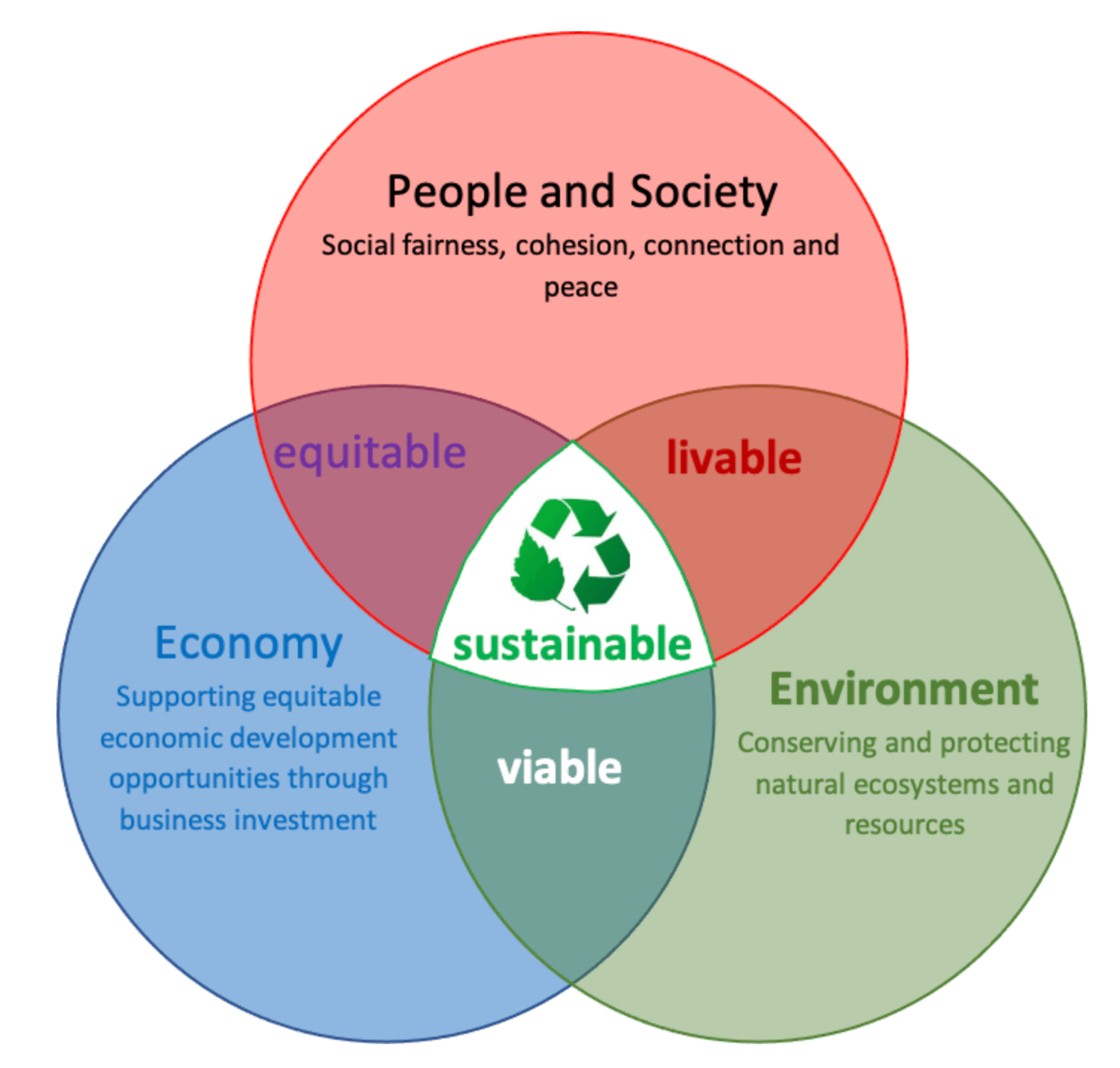

Clever Power believe that the energy conversion concept can contribute to a better world but we cannot achieve the UN sustainable development goals without excellence in engineering and science.

Clever Power agrees with the UN sustainable development goals which state; “Inclusive and sustainable industrialisation, together with innovation and infrastructure, can unleash dynamic and competitive economic forces that generate employment and income. Innovation and technological progress are key to finding lasting solutions to both economic and environmental challenges, such as increased resource and energy-efficiency.”

Clever Power see affordable clean energy as key to improvements in human health, food security, education and the reduction of poverty. It is needed to minimise global warming.