Waste to Fertiliser, Sustainable, Productive Farming

Fertiliser Production - Nutrient Recovery

They are many wastes which are rich in nutrients. However, society does not typically recovery these nutrients as they comingled with pathogens, have an offensive smell, are difficult to handle and distribute and they are mixed with sharp objects and plastics.

Clever Power can overcome these difficulties to produce a composted, organic, slow release, heat-treated, fertiliser. Today, there are small-scale production of organic fertilisers in Southeast East Asia and Indo-Pacific Islands. Clever Power seeks to improve on these ancient organic farming methods to lower fertiliser cost, increase nutrient concentration and reducing odour and eliminating pathogens.

What Nutrients are Recovered?

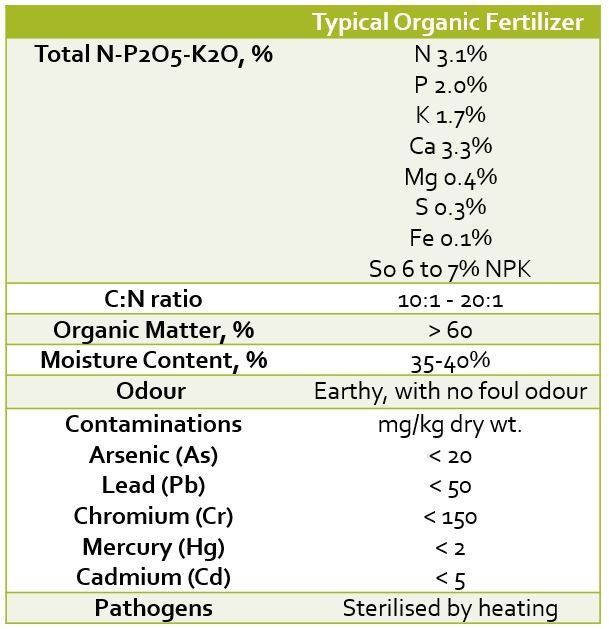

We need productive farming to feed the world. Good fertilisers are rich in both macro and micro-nutrients. The macro nutrients are Nitrogen (N), Phosphorous (P) and Potassium (K). There are 7 essential micro plant nutrients, these being Boron (B), Zinc (Zn), Manganese (Mn), Iron (Fe), Copper (Cu), Molybdenum (Mo), Chlorine (Cl)]. They typically constitute in total less than 1% of the dry weight of most plants. For some soils, Calcium (Ca), Magnesium (Mg) and Sulphur (S) are added to the list of micronutrients. According to Liebig’s law the productivity of a crop is not dictated by total nutrients available, but rather by the scarcest nutrient which is the limiting factor for plant health and growth. The production of healthy crops requires the availability of all the plant nutrients in the correct ratios.

There are three types of fertilisers:

• chemical,

• organic and

• bio-fertiliser (legumes and micro-organisms).

Each type of fertiliser has its advantages and disadvantages. These advantages need to be integrated in order to achieve optimum performance by each type of fertiliser and to realise balanced nutrient management for each crop.

Peak Phosphorus

Phosphorus is a finite (limited) resource that is widespread in the Earth's crust and in living organisms but is relatively scarce in concentrated form. The recycling of phosphorus, through the reuse of animal manure and human excreta, in agriculture went out of fashion from the 1800’s with the discovery of guano on many remote islands. The guano supply of phosphorous is now largely exhausted. We may be using up phosphorus rock faster than we are finding new phosphorous ore bodies. A shortage in phosphorus rock (or just significant price increases) might negatively affect the world's food security. Whilst there is debate about whether we have reached “Peak Phosphorous” or not, there is a need to recycle nutrients (especially P).

Clever Power’s Fertiliser Production

In addition to power, three co-products from the Clever Power patent pending process are biochar, nutrient rich scrubber water and waste heat at about 130oC.

The biochar is principally derived from cellulose, and it is activated. Activated in this sense means the char has millions of micro pores and channels within the char that trap and slow down the leaching of N, P and K from soil when the char is added to that soil. The biochar is also relatively rich in P, K, B, Zn, Mn, Fe, Cu, Mo, Cl, Ca Mg and S in roughly the ratios that is useful for plant growth.

The nutrient rich scrubber water contains undesirable chemicals like ammonia (NH3), calcium nitrate (Ca(NO3)2), calcium chloride (CaCl2) calcium sulphate (CaSO4), and Potassium Oxide (K2O). Often the calcium version of the compound has a magnesium version also present. When air is added to this water the chemicals turn into fertiliser compounds like ammonium nitrate (NH4NO3), ammonium sulphate (NH4)2SO4), calcium carbonate (CaCO3), magnesium carbonate (MgSO4) and potassium carbonate (K2CO3).

Manure is rich in macro and micronutrients. The ancient Egyptians, Chinese and Greeks all made fertiliser in cesspits from human and animal manure. Composting the manure reduces the concentration of pathogenic bacteria and converts the urea to ammonia and the ammonia to nitrates. The waste heat from the Clever Power process can be used to kill the pathogens found in composted manure, thereby sterilising and de-odorising the composted manure.

Clever Power have developed their own nutrient recycling process. We use the co-products of the power generation plant to make a composted, organic, slow-release, heat-treated fertiliser. Like other organic fertilisers (Chen (2006)) the advantages of

Clever Power’s fertiliser is:

- The nutrient supply is more balanced compared with other fertilisers, which helps to keep plants healthy.

- They enhance the soil’s biological activity, which improves nutrient mobilisation from organic and chemical sources and decomposition of toxic substances.

- They enhance the colonization of mycorrhizae, which improves P supply. Mycorrhizae are mutually beneficial (symbiotic) relationships between fungi and plant roots.

- They enhance root growth due to better soil structure.

- They increase the organic matter content of the soil, therefore improving the cation and anion exchange capacity of nutrients, increasing soil water retention, promoting soil aggregates and buffering the soil against acidity, alkalinity, salinity, pesticides and toxic heavy metals. The activated carbon in the Clever Power fertiliser makes this statement even more true compared to other organic fertilisers.

- They release nutrients slowly (the Clever Power fertiliser even slower than some other organic fertiliser) and contribute to the residual pool of organic N and P in the soil, reducing N leaching loss and P fixation; they can also supply micronutrients.

- They supply food and encourage the growth of beneficial micro-organisms and earthworms.

- They help to suppress certain plant diseases, soil-borne diseases and parasites.

- There is much less nutrient leachate from the soil to local creeks and rivers or lost to atmosphere. Over application of chemical fertilisers has resulted in the negative effects of leaching, water pollution and destruction of micro-organisms and friendly insects, leaving the crop susceptible to disease attack, acidification or alkalisation of the soil or reduction in soil fertility — thus causing irreparable damage to the overall system. Chemical nutrients are easily lost from soils through fixation, leaching or gas emission and can lead to reduced fertiliser efficiency.

Some of the issues to consider when using organic fertilisers

- They are comparatively low in nutrient content compared to some chemical fertilisers, so larger volumes may be needed to provide enough nutrients for crop growth.

- The nutrients release rate maybe too slow to meet some crop requirements in a short time, hence some chemical fertiliser may still be required at a reduced rate at some points in the cropping cycle.

- The major plant nutrients may not exist in organic fertilizer in sufficient quantity to sustain maximum crop growth, hence some chemical fertiliser may still be required at a reduced rate at some points in the cropping cycle.

Combined use of fertilisers

Chen (2006) reports that there is increased need to limit environmental impact of the continuous use of chemical fertilisers. An integrated nutrient management system is required. This system is characterized by reduced input of chemical fertilizers and combined use of chemical fertilisers with organic materials such as composted and sterilised animal manures, crop residues, and green manure (mulch nitrogen rich leaves). For sustainable crop production, integrated use of chemical and organic fertiliser has proved to be highly beneficial. Several researchers have demonstrated the beneficial effect of combined use of chemical and organic fertilizers to mitigate the deficiency of many secondary and micronutrients in fields that continuously received only N, P and K fertilizers for a few years, without any micronutrient or organic fertiliser. The use of organic fertilisers together with chemical fertilisers, compared to the addition of organic fertilisers alone, had a higher positive effect on microbial biomass and hence soil health. Application of organic manure in combination with chemical fertiliser has been reported to increase absorption of N, P and K in sugarcane leaf tissue compared to chemical fertiliser alone.

Clever Power look forward to working with Pilipino agronomists on the island of Mindanao to elucidate the best ways to:

• Reduce local dependency on chemical fertiliser

• The appropriate mix of fertilisers and

• When to add them for the pineapple, rice, sugar cane and corn crops.

The some of the above is summarised from:

Jen-Hshuan Chen (2006)

“THE COMBINED USE OF CHEMICAL AND ORGANIC FERTILIZERS AND/OR BIOFERTILIZER FOR CROP GROWTH AND SOIL FERTILITY”

Department of Soil and Environmental Sciences, National Chung Hsing University, Taiwan, R.O.C.